Stanton Iron Works

HISTORY OF STANTON WORKS

Stanton Ironworks in Ilkeston officially ceased production on May 24, 2007, when the final pipe was cast. This marked the end of an era for the remaining 185 production workers, who left the factory for the last time.

Stanton Ironworks: A Pillar of Industry

For decades, Stanton Ironworks was Ilkeston’s largest manufacturing enterprise and its primary employer. The Stanton and Staveley group was incorporated into the British Steel Corporation's Tubes Division. At its peak, the company employed around 12,500 workers, with 7,000 based at Stanton.

Origins and Growth

Evidence suggests that iron production in the area dates back to Roman times, with medieval bloom furnaces discovered at Stanley Grange near West Hallam. The industrial journey began in 1788 with a small blast furnace near Stanton by Dale, laying the foundation for the area's thriving iron industry.

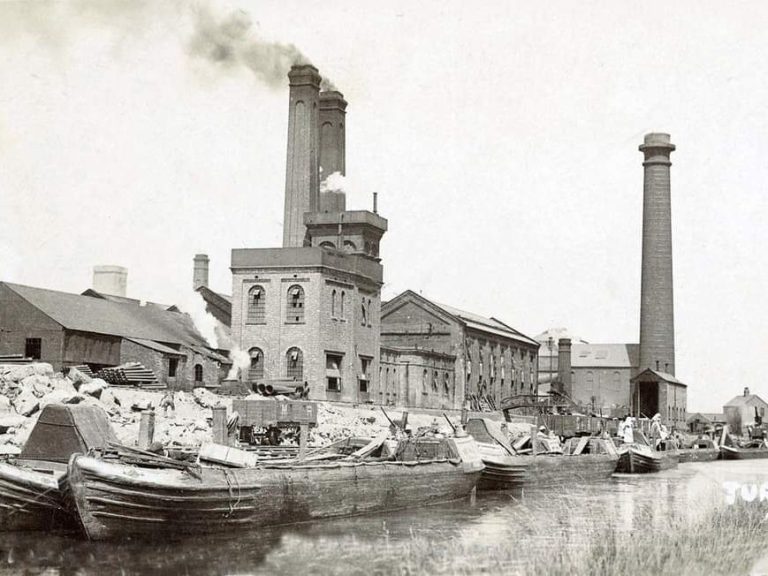

The official origins of Stanton Ironworks trace back to 1846, when Benjamin Smith and his son Josiah established three blast furnaces near the Nutbrook Canal. By 1867, these were replaced by five new furnaces, forming what became known as the "Old Works." Despite financial difficulties, the Crompton family took over and renamed the enterprise The Stanton Iron Company.

The Franco-Prussian War of 1870 spurred rapid expansion, leading to the construction of the "New Works" by the Erewash Canal in the early 1870s. By the early 20th century, the company operated as The Stanton Ironworks Company Ltd.

Mergers and Nationalisation

In 1960, Stanton merged with the Staveley Iron and Chemical Company Ltd under Stewarts and Lloyds Ltd, becoming Stanton and Staveley. Seven years later, it joined the British Steel Corporation through nationalisation.

Production Legacy

Stanton's range of products was extensive:

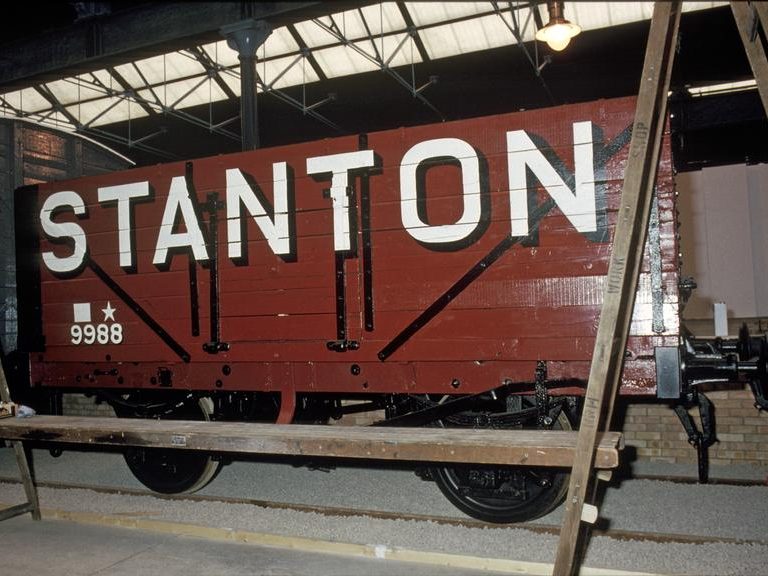

Spun iron pipes and pig iron

Pre-stressed concrete pipes

Street furniture and lighting columns

Cast-iron tunnel segments for projects like the London Underground and Mersey Tunnel

Stanton also contributed chemicals, coke oven gas, bitumen, and road-stone. During both world wars, it played a critical role in producing artillery shells, bomb casings, and even experimental concrete torpedo casings. Notably, the Stanton Gate Foundry produced 873,500 bomb casings during World War II.

Post-War Changes

Post-war years saw Stanton's fortunes fluctuate due to shifts between nationalisation and privatisation. In the 1980s, it became part of the French Pont-a-Mousson Group and later Saint-Gobain.

Decline and Legacy

Today, much of Stanton Ironworks has been demolished, with most of the remaining structures being cleared for housing development. Deb Wrekon, our sculptor was able to use the last pipe ever made at Stanton Iron Works in part of her sculpture.

Despite the challenging and often dangerous working conditions, Stanton’s workforce was known for its camaraderie and resilience.

This history honours Stanton Ironworks as a vital part of Kirk Hallam's industrial heritage and a testament to the strength of its community.

Acknowledgments: Saint Gobain, StantonIronWorks.co.uk, Erewash Museum, IDLHS (Ilkeston and District Local History Society, Stanton and Staveley, https://calmview.derbyshire.gov.uk

Websites; Stanton Iron Works

Films and Videos

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.